Green Hydrogen

The industrial methods for generating hydrogen gas

Most hydrogen is produced from fossil fuels by steam reforming of natural gas and other light hydrocarbons (blue hydrogen), partial oxidation of heavier hydrocarbons and coal gasification (grey hydrogen). Other methods of hydrogen production include biomass gasification, no CO₂ emissions methane pyrolysis and electrolysis of water.

The production of green hydrogen

Green hydrogen is hydrogen generated by renewable energy or from low-carbon power, and has significantly lower carbon emissions than grey hydrogen. Green hydrogen is produced by the electrolysis of water.

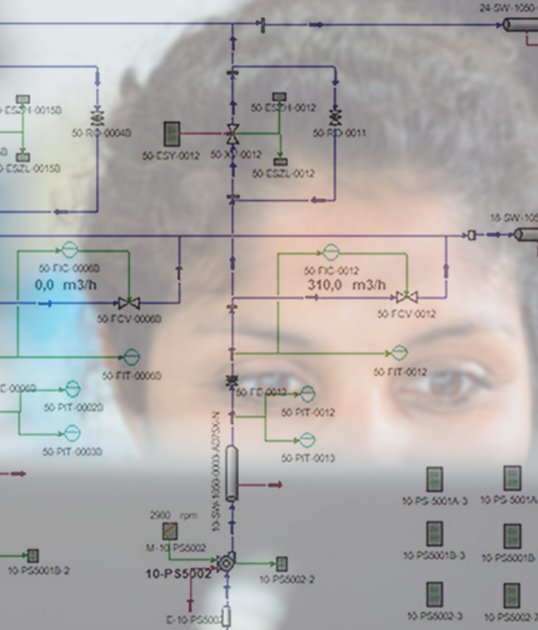

Developing high-fidelity simulators of hydrogen processes introduces several challenges as mainstream simulators do not have ready-made models for the various types of electrolysis cells.

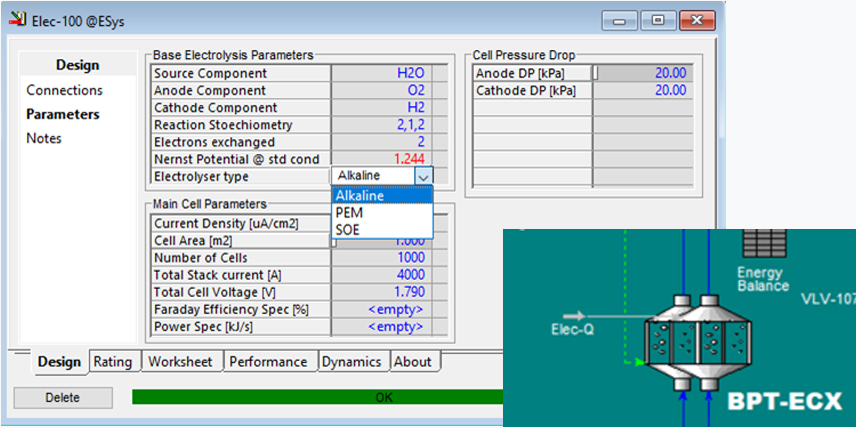

BPT has developed a flexible and unique electrolytic separator cell model called BPT-ECX that works as an extension to industry-leading process simulators like HYSYS, UniSim and Petro-SIM (run as a fully integrated unit operation within these simulators).

The BPT-ECX includes models for the following types of electrolysis:

- PEM (Polymer Electrolyte Membrane electrolysis).

- AEL (Alkaline ElectroLysis).

- SOEC (Solid Oxide Electrolyze Cell).

The uniqueness of BPT-ECX:

- BPT-ECX facilitates accurate interactive steady state and dynamic simulation of electrolysis plants without the need for process engineers that have specialist knowledge of advanced simulation tools (user-friendly).

- BPT-ECX is fitted for standalone models of the electrolysis stack units or in simulation models where electrolysis is a part of a larger plant where the interaction and controllability between the various parts are of crucial importance to validate and improve.

- BPT-ECX enables transfer of experimental data of newly developed electrolysis cell technology into an overall electrolysis plant model to evaluate the new technology and design pilot and industrial plants.

Some of the key parameters included in BPT-ECX:

- Area and number of cells.

- Flexible geometry (vendor specific).

- Electrolysis efficiency and over-potential.

- Voltage cell.

- Faraday efficiency.

- Gas purity.

- Heat loss.

- Thermal lag.

Green Ammonia

Ammonia is one of the most produced inorganic chemicals

Historically, ammonia has mainly been used for fertilizing agricultural crops. More recently, ammonia is considered to be a future energy carrier of hydrogen or an alternative fuel for ships etc.

Ammonia is produced in a process known as the Haber Bosch process, in which nitrogen and hydrogen react in the presence of an iron catalyst to form ammonia. Hydrogen is formed either by reacting natural gas and steam at high temperatures (grey ammonia) or through electrolysis using green power. The nitrogen is supplied from an air separation unit that could also be driven by green power.

The production of green ammonia

Production of green ammonia requires green hydrogen produced by electrolysis, nitrogen separated by green power, compression to high pressure and a Haber Bosch reactor.

Developing high-fidelity simulators of ammonia processes introduces several challenges as mainstream simulators do not have high-fidelity and dynamic models for green hydrogen and high-fidelity Haber-Bosch reactors.

For green hydrogen production, BPT has developed a flexible and unique electrolytic separator cell model called BPT-ECX (see Green Hydrogen for details).

For Haber-Bosch, BPT has developed a highly accurate and fully dynamic unit operation named BPT-HB that works as an extension to industry-leading process simulators like HYSYS, UniSim and Petro-SIM (run as a fully integrated unit operation within these simulators).

The uniqueness of BPT-HB:

- Steady state and dynamic with full lifecycle capabilities.

- Easy to implement different correlations with different kinetic parameters.

- Allows for varying and tunable heat transfer throughout the reactor.

- Supporting different heating / cooling medium types in both steady and dynamic modes.

- Fitted for standalone models of the Haber-Bosch reactor or in simulation models of a larger plant.

- Includes catalyst degradation features.

- Model thermal lag effects.

- Design for flexible geometry (fixed bed, radial, etc.).

- Tailor-made thermodynamic property package (on demand).

Electrofuels

Carbon-neutral synthetic fuels (synfuel) and other fossil replacement products

A typical e-fuel process includes CO2 captured from air or a point-source emission of CO2 or CO from concentrated industrial combustion emission, processed through synthesis (syngas) reactor, electrolysis (adding water and renewable power) and Fischer-Tropsch synthesis reactor turning synthesis gas into fuels like Jet-Fuel (Kerosene), Naphtha, Diesel and Wax.

Developing high-fidelity simulators of synthetic fuel processes introduces several challenges as mainstream simulators do not have high-fidelity and dynamic models for green hydrogen and Fischer-Tropsch reactors.

State-of-the-art E-Fuel simulator with fully dynamic capabilities

For green hydrogen production, BPT has developed a flexible and unique electrolytic separator cell model called BPT-ECX (see Green Hydrogen for details).

For Fischer-Tropsch, BPT has developed a highly accurate and fully dynamic unit operation named BPT-FT that works as an extension to industry-leading process simulators like HYSYS, UniSim and Petro-SIM (run as a fully integrated unit operation within these simulators).

The uniqueness of BPT-FT:

- Steady state and dynamic with full lifecycle capabilities.

- Facilitates for varying α-factor throughout the reactor - easy to implement different correlations with different kinetic parameters.

- Allows for varying and tunable heat transfer throughout the reactor.

- Supporting different heating / cooling medium types in both steady and dynamic modes.

- Fitted for standalone models of the Fischer-Tropsch reactor or in simulation models of a larger plant.

- Includes catalyst degradation features.

- Model thermal lag effects.

- Design for flexible geometry (fixed bed, radial, etc.)

Green Methanol

Green methanol plant

A typical green methanol plant includes a feedstock of CO2, electrolysis (adding water and renewable power), a Methanol synthesis reactor turning carbon dioxide into methanol/water and separation/stabilization unit creating methanol used as fuel.

Developing high-fidelity simulators of synthetic fuel processes introduces several challenges as mainstream simulators do not have high-fidelity and dynamic models for green hydrogen and methanol reactors.

High-fidelity methanol simulator with fully dynamic capabilities

For green hydrogen production, BPT has developed a flexible and unique electrolytic separator cell model called BPT-ECX (see Green Hydrogen for details).

For the methanol reactor, BPT has developed a highly accurate and fully dynamic unit operation named BPT-MR that works as an extension to industry-leading process simulators like HYSYS, UniSim and Petro-SIM (run as a fully integrated unit operation within these simulators).

The uniqueness of BPT-MR:

- Steady state and dynamic with full lifecycle capabilities.

- Easy to implement total reactor volume in different segments assuming perfect mixing.

- Implementation of rigorous kinetic parameters.

- Allows for varying and tunable heat transfer parameters throughout the reactor.

- Supporting different cooling medium types in both steady and dynamics.

- Suitable for standalone models of the MR reactor or integrated simulation model with a larger plant.

- Catalyst degradation and its effect.

- Model thermal lag.

- Flexible geometry.

CCUS

The process of capturing carbon dioxide (CO2) before it enters the atmosphere

Usually, the CO2 is captured from large point sources, such as coal-fired power plants, cement kilns, chemical plants and biomass power plants. It is then stored in an underground geological formation or reused in the production of high-value chemicals to prevent the release of CO2 from heavy industry.

Carbon Capture, Utilization and Storage (CCUS) systems causes several challenges for simulator modelling because it uses a variety of technologies, including absorption, adsorption, chemical looping, membrane gas separation and gas hydration. This requires special attention to thermodynamic properties used in the process and modelling of the various unit operations.

Carbon capture, utilization and storage simulator

BPT has the capabilities to create tailormade simulators for CCUS and develop extensions to industry-standard simulators to close the gap of shortcomings and fidelity.

Air Separation Unit (ASU)

Cryogenic heat exchange

Air separation plants separate atmospheric air into its primary components - nitrogen, oxygen and argon.

Simulator modelling of cryogenic air separation, which utilizes the differing condensing/boiling points of the components of air to enable separation by distillation at cryogenic temperatures, is challenging and often leads to results with a lot of uncertainty.

Accurate ASU simulator

BPT has unique and hands-on expertise in modelling such complicated equipment units, combining a deep understanding of simulator unit operations and thermodynamics as well as how to reconfigure/tune commercial process simulators to highly accurate solutions adding value.

Direct Air Capture (DAC)

Direct air capture of CO2

Based on adsorption processing, air is separated in CO2, oxygen and nitrogen, where the CO2 is injected in the ground (reservoirs) or transported for utilization.

DAC simulator

BPT has ongoing developments to facilitate accurate dynamic models of DAC systems. These models will be used throughout the lifecycle from early concept design, engineering, commissioning startup and performance monitoring during operation. This also includes control system validation and operator training.

Concentrated Solar Power (CSP)

CSP with supercritical CO2 as energy carrier

Supercritical CO2 as the working fluid in a closed-loop recompression Brayton cycle has demonstrated high efficiency and compact equipment sizes (compared with the traditional superheated steam cycles) at temperatures relevant for CSP applications.

Experience with industry-standard process simulators and most used thermodynamic packages shows slow speed performance for pure CO2 and severe challenges meeting speed and accuracy requirements. The impact of CO2 impurities is high, resulting in lower fidelity simulator accuracy.

Simulator with supercritical CO2

BPT together with thermodynamic property experts, has worked out a new successful implementation of thermodynamic Equation of State (EOS) handling CO2 impurities in simulators that improve speed and accuracy performance for supercritical CO2 processes.

Biofuels

Organic materials (biomass) transformed into fuel such as ethanol and the biodiesel

Biomass can be converted to fuel by pyrolysis, hydrotreating or gasification. They mainly differ in the process temperatures and the amount of oxygen present during the conversion process. Pyrolysis entails heating organic materials in the near-complete absence of free oxygen. Biomass pyrolysis produces fuels such as charcoal, bio-oil, renewable diesel, methane, and hydrogen. Hydrotreating is used to process bio-oil (produced by fast pyrolysis) with hydrogen under elevated temperatures and pressures in the presence of a catalyst to produce renewable diesel, renewable gasoline, and renewable jet fuel. Gasification entails heating organic materials with the injection of controlled amounts of free oxygen and/or steam to produce synthesis gas. Syngas can be used as a fuel or as feedstock to produce liquid fuels.

Biomass is not defined in the traditional compositional way; it is rather characterized in terms of atomic composition. This composition needs to be converted to molecules to enable modelling in the process simulators. The reaction paths and kinetics of pyrolysis, gasification and hydrotreating may be complex and in a form not immediately suitable for use in a simulator.

Simulator for biofuel plants

BPT has the capabilities to model biomass and its conversion to molecules. BPT can package the specific kinetics and reaction paths in an easy-to-use package, suitable for process engineers as well as being used as lifecycle simulators.

/cam-a805c25e-9cf0-f60f-73fb-93606b2da1f9.jpg)

/cam-4d7cebe3-80d8-e066-3aab-02619dc279a5.jpg)

/img-e540287e-7e8a-78ef-c73e-ae0333117742.jpg)